How to Choose and Customize Your HVLP Turbine Spray Finishing System

One of the questions I’m asked, time and again, is how to go about choosing an HVLP turbine spray finishing system.

So I’ve decided to give my spin on this important question – without resorting to too much technical detail – in the hopes that it’ll help those of you how are deciding which system to get. And while I’m at it, I thought I’d also throw in a few ideas to consider when it comes time to customize your system to make it more useful to you.

How HVLP Turbines Work

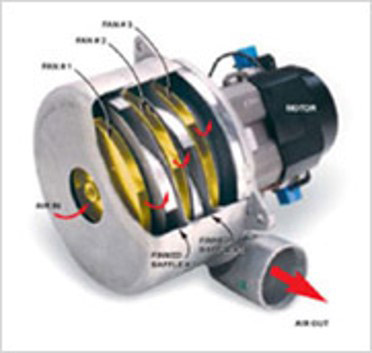

Before we get into selection criteria, I thought it best to start with some basic info on how turbines operate. Looking at the below cutaway diagram, you’ll see the high-speed electric motor on the right and the turbine housing to its left.

The turbine housing is divided into separate chambers (we call them “stages”).

With the turbine motor spinning, air is drawn into the opening on the left end of the turbine and into the 1st impeller stage.

There, the air is compressed then sent down the line and into the 2nd stage. That next impeller increases the air pressure and volume even further, sending it along to the next stage…then the next and so forth until exiting the final stage of the turbine.

Simply stated, the more stages a turbine has, the greater the air pressure and volume it can generate. You’ll soon see why that’s important.

Of course, a turbine system consists of not only a turbine, but a spray gun and connecting hose.

And just like most things in life, better quality spray guns have more attention given to their engineering and machining and are made from higher quality materials. You really do get what you pay for.

4 Questions to Help You Select an HVLP Turbine Spray System

Question 1: What Materials will you be Spraying? Let’s face it, whatever system you buy needs to be able to spray the finishes you’ll be using.

If they’re mostly low viscosity (“thin”, in layman’s terms) finishes such as Target Coatings’ Emtech EM1000 Universal Sanding Sealer or EM6000 Production Lacquer in the photo’s left group, 2-stage and larger (3, 4 or 5-stage…) HVLP turbine systems can successfully spray them without needing thinning.

Medium viscosity (somewhat “thicker”) finishes such as Emtech Varnish or NR4000 Stain Base in the center group need the additional air pressure and volume of 3 and higher-stage HVLP turbine systems to be atomized successfully without resorting to any thinning.

But that doesn’t necessarily mean that a 2-stage turbine won’t be able to work with them, as many of these finishes can be thinned by as much as10% without causing difficulties.

But when you get to the third group – high viscosity finishes such as Emtech’s Pigmented Lacquers – nearly all HVLP turbine systems will require thinning to a lesser or greater degree. In all cases, check with your finish distributor to see how much thinning a product can tolerate.

Pro Tip: When it comes to thinning, the general rule is “thin only when required, and use as little thinner as possible”

Question 2: What Products and Volume of Work will You be Doing? If you plan on spraying mostly small pieces such as the jewelry box shown below, with all things being equal, most any system will do the job.

The reason is, although you may have to somewhat narrow the spray pattern thereby concentrating the limited air pressure and volume for a 2-stage system, you can get away with it because of the small job size.

But if large cabinets – and plenty of them – are mostly what you’ll be spraying, you’ll need to set up for a wide fan pattern to give you the coverage to efficiently getting things done. And that means you’ll need more air pressure – which comes only with more turbine stages.

Question 3: Is Noise Level a Consideration? If you’re planning to do on-site work at a client’s location (home or business), then you may be in the market for a turbine that’s designed to operate quietly.

That same characteristic may also be important if your shop is located in your garage or basement and you’re a DIYer or Part-time Pro and don’t want to disturb your family in the off-hours. But bear in mind that the additional engineering needed to provide this feature comes at a 25% cost increase. And that brings us to the final question…

Question 4: What is your Budget? Once you’ve decided which system (or systems) will meet your needs, then it’s time to look at your budget. And with entry-level units costing under US $500 and even quiet 5-stage turbine HVLP systems running at US $1,549, there’s a price point sure to please nearly every budget.

Accessorizing your System

Okay, so once you’ve selected your system, the next thing to look at are spray system accessories.

Shown above are my three most favorite ones, beginning with the turbine remote controller (I hang mine from my belt via a carabiner). This accessory allows you turn your turbine on and off at the press of a button.

Then, for those of you who’ll be spraying a wide range of different products, you’ll need a few different aircap sets (consisting of the nozzle, needle and aircap). In most cases you’ll only require two additional ones: a .8 and a 1.8 or 2.0 set. (a 1.3 comes standard with most systems).

My final recommended accessory is the 3M PPS “pressure cup” system. This add-on will enable spraying at any attitude – even upside down – to make spraying that much easier (think: cabinet insides and chairs). It also makes for quicker cleaning.

I hope that this article helps those interested in buying an HVLP turbine spray system and those looking at accessories.

And as always, throw me your questions and comments below. I’m here for you.