Have you ever needed to set up a temporary spray finishing area in your shop?

If you’ve read my previous Target Coatings blog posts and/or follow me on social media, you know I have a spray booth in my shop.

But that wasn’t always the case.

And based on discussions I’ve had with lots of part-time pros and serious woodworkers, many of them don’t have access to a spray booth most or all of the time, either.

That doesn’t mean you can’t safely spray water based finishes in your shop — even if it’s connected to or a part of your home.

That said, there are a few cardinal rules you’ll need to follow.

In this article (and the accompanying video below) I’ll show how you can set up a temporary spray finishing area in your shop to help you get pro-quality results.

And for those of you thinking about taking the next step and making a bare-bones permanent or portable spray booth, in Part 2 I’ll give you a few different configurations to consider.

For now, lets get jump into Part 1 of this article: how to set up a temporary spray finishing area inside your shop for spraying water based finishes.

Please Note: despite the safety measures mentioned below, the process described here could be dangerous and is therefore intended for informational purposes only and for people having appropriate technical knowledge, experience, and skill to consider and use at their own discretion and risk.

CARDINAL RULES

There are three rules you must follow:

1. Turn off Air-handling Systems Fans. While actively spraying, turn off the fans on any air conditioning/heating systems that circulate air within and into your shop. This will keep any overspray (yes even HVLP systems generate a certain amount) from clogging filters and/or possibly causing problems with these systems.

2. Only Spray Water Based Products. It can’t be emphasized enough that the procedures described here are only to be used for spraying non-flammable products. If you’re planning to spray anything else indoors, a certified spray booth that meets the applicable local codes is required.

3. Wear a Respirator. Get yourself a well-fitting respirator that protects against organic vapors and wear it every time you’re spraying. Yes, even if only doing a quick touch-up. Keep others (pets, too) out of the shop when spraying is in operation, or ensure they’re also wearing respirators.

SETTING UP THE TEMPORARY SPRAY FINISHING AREA

Now that we understand the cardinal rules, let’s get down to setting things up.

1. Select Your Spray Finishing Area. Let your shop layout determine where to set up your spray finishing area. Don’t be shy about temporarily relocating mobile machines to other parts of the shop to give you the space you’ll need.

2. Get Rid of Dust. This is a two-part process:

Part 1: Because we know that dust floating around the spray area is likely to find its way onto freshly sprayed pieces and ruin them, clear away the dust from your shop (or at least the spray area). I’ve found that using a leaf blower the night before works really well. I usually start at the ceiling and work my way down the walls and then to the machines and floor. Yes, the dust will fly around, but by working your way from one area to another in a logical pattern, you’ll eventually get most of it cleared away.

Part 2: Vacuum away Remaining Dust. Once the dust has settled, use your shop vacuum to get rid of the dust you kicked up. Don’t bother trying to create an operating room environment! We just want to create as dust free an environment as we reasonably can.

3. Cover any machines, workbenches, etc. with drop cloths or moving blankets. This will keep any overspray from settling onto them.

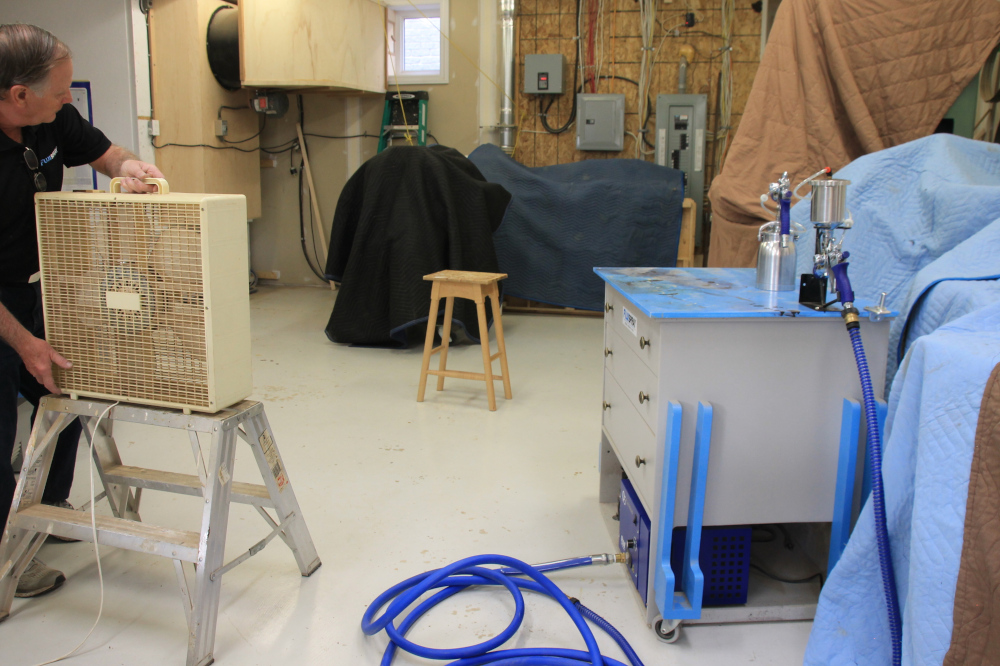

4. Position Work Support, Fan & Air Source. Start by positioning the work support you’ll be placing your pieces on. In this example I’m using my shop stool, as it’s about the right height for comfortably spraying most things.

I then position the fan I use to gently blow away any overspray from the pieces during spraying. As you can see, it’s an inexpensive box fan (I picked it up at a local thrift store). I place it atop a folding step ladder, which brings it to approximately the same height as the work support. I’ve found that with fans like this set to high speed, 10 feet away from the work support is about right.

Now that you know where any overspray will be moving, go ahead and position your air source outside of that path. In this example, it’s my Fuji Spray Q5 Platinum turbine which I’ve mounted inside my spray cart that houses everything I normally need for spraying.

5. Set up Lights & Drying Area. Because of the importance of being able to see where you’re spraying, move a portable LED lighting fixture close to the action. Then go ahead and select the drying area where you’ll set freshly sprayed pieces to dry. I suggest this always be outside of the air movement path, and as close to the spraying area as possible.

Then ensure you have a clear route between the work support and the drying area. In the example below, see the air supply hose positioned perfectly to trip me up!

6. Safety: Fire Extinguisher & Respirator. Ensure you have a fire extinguisher at the ready. And as mentioned in the Cardinal Rules, ensure you wear a properly fitting respirator. The above photo shows my full face model beside the half-face one I use for general shop work.

7. Test, then Go! With everything set up, I do a test run spraying tap water, just to ensure I’m happy with how things are positioned and performing. Now go ahead and enjoy your spraying session!

Want a little more “color” on this entire process? Check out this step-by-step video…

If you have questions, comments, or want to share your experiences with setting up a temporary spray finishing area, please post your thoughts in the comments section below. I’m here for you!

Great overview and tips Marty. Thanks

What are the lids on top of the two cans of finish in the background?

Helpful tips Marty, thanks.

Mike – They look like the MixingMate lids that are sold at Rockler and other DIY woodworking outlets.

-JeffW-

Thanks so much, Marty! Super helpful! Looking forward to Part II….

Bill

Can you comment on the explicit call for a fire extinguisher when limiting to water based coatings? Is there a specific reason in this application beyond just a good idea to have one in the shop?

MD – Thank you for your inquiry. AN ABC Fire Extinguisher should be standard equipment in all workshops, home or commercial.

While water based finishes and their overspray are not combustible or flammable there is always the potential fire hazard in any workplace

-JW-

Thank you!